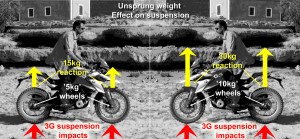

Writing up my 9000-km review over Christmas, I realised how much the Honda’s 35.2″/894mm seat height was bugging me. And it wasn’t just me. In 2023 Honda introduced a 2-inch-lower CRF300LS model, achieved by slightly shorter suspension components. An appealing non-red colour scheme apart, it’s otherwise identical, though currently not sold in the UK.

According to the guy above, no seat foam was harmed in producing the LS: ‘Honda shortened the suspension…’. But he then goes on to say ’rear travel is reduced by 1.2”’. Does he actually mean shock length is reduced by 1.2”’ (to make 2” less vertical travel)? Probably.

Riding the trails, my suspension travel is way more than I ever need – an LS would have done me nicely – though once compressed the height’s rarely an issue unless I tackle technical terrain. Very occasionally the back bottoms out as it should; the front not yet. With me it’s more the getting on and off, which I do a lot of and gets more tiresome as the years pile on. Along with comfort, these two things hold back my enjoyment on the L. Fitting the 17/19 wheel combo didn’t lower the bike significantly.

So I bought one of those suspension lowering links which I’ve read about for years. I recall my KLX had a clever adjustable link. US-made Kouba Link is the well known brand, but costs nearly £200 in the UK. I settled on a similar looking ‘Schmooba Link‘ off ebay for just £42 with the same needle bearings and grease nipple. NICECNC may be made in China but have a decent-looking website and a huge range of parts.

They say these links can mess up the carefully mapped factory linkage ratios working on the shock spring. That may be an urban myth or something that only applies to performance-sensitive racers. The link swap took just 10 minutes with a helping hand of Larbi in Marrakech.

My Schmooba claims to lower the bike by 1.75″ (44mm; identical to Kouba) which is a bit more than I need, but tbh it didn’t look that much lower. Once fitted, I jacked the Tractive shock preload up a turn and a bit. What a faff that is. The shock is clearly made for an HPA and not manual adjustments. The job is made harder with the need to loosen a grub screw locking the preload collar in place. The supplied multi-bit tool has a 2-3mm bit to get in there (left); you then need a 5mm spanner to turn it, as long as the screw is in an accessible location.

There is no crenelated preload ring to hook with a c-spanner, but a series of holes in the collar, like on a wagon wheel hub (above). The multi-bit tool is too short and bulky; a 5mm rod or screwdriver works better, you inch the ring round; it’s easier on the RHS, and I found it best with a 5mm L-shaped Allen key and an additional extension/lever. Give it all a squirt of WD40 too. It takes about 12-15 micro-adjustments to get a full turn of the collar. I kept going until the annoying grub was accessible again and hope that’s enough.

Of course the forks need sliding up the triple clamps to match the rear drop – easily done. But without risers, the stock height bars limit the drop to about 25mm. So 25mm it will have to be; I hoped the jacked-up shock would compensate for the now moderately raked out fork.

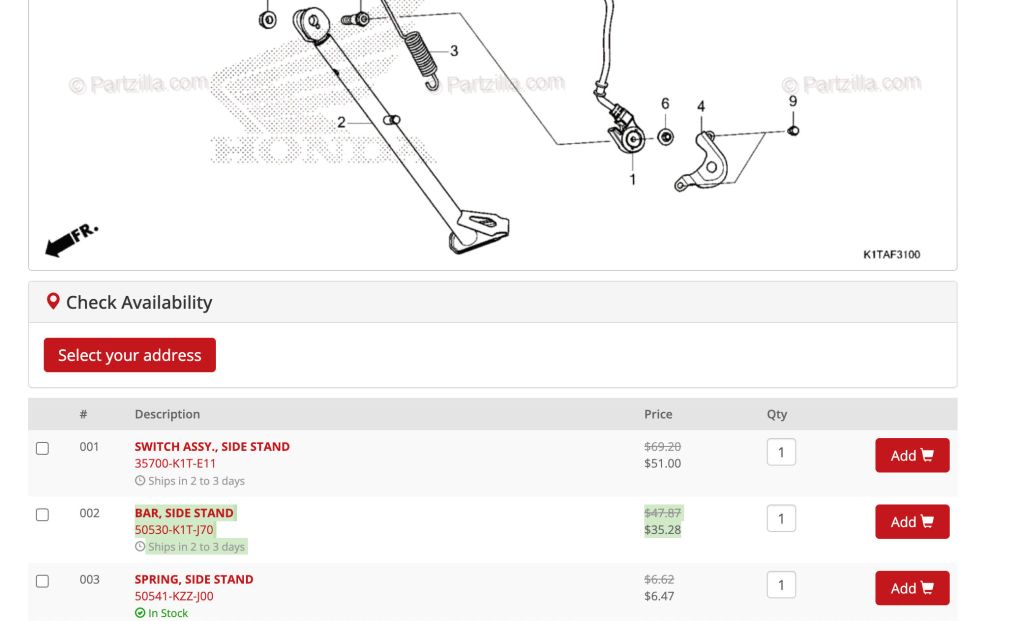

If you’re lowering your 300 you’ll need a shorter side stand. RRP do 20mm shortie for £88. Or so I thought. With forks raised and link fitted it actually didn’t lean too bad. It turned out a new oversized Mitas E07 tyre on the back raised the bike back up an ~inch. Then, offering up the RR short stand, it turned out to identical. Have I been on a short side stand all this time or did they send the wrong one? Oh well, one less job to do.

Is an OEM stand for the 300LS on Partzilla US shorter?

Two are two stands listed but which was which? Knowing that the 300LS model code is probably CRF300LDA ABS is helpful.

- Lowered 300LS CRF300LDA ABS side stand: 50530-K1T-J70

- My bike 300L ABS side stand: 50530-K1T-E50

In fact a -J70 shortie is bent; the normal height -E50 is straight. And if you look up 300LS reviews online you’ll see they have a bent side stand, unlike a normal 300L, even though the Honda parts fiche shows a straight stand for both parts. Hence my fiche confusion.

A J70 is discounted to $35 on Partzilla US. In the benighted UK an E50 is £48 but I actually got offered a bent J70, which was actually what I was looking for. Fascinating a?! But wait, there’s more! A bent J70 is shorter. The reason it was bent because a straight stand on the lowered LS might drag on full suspension compression. So it seems Honda bent and shortened a stock 50530-K1T-E50 to make 50530-K1T-J70 for the 300LS, but online fiche images appear identical.

Now, about an inch lower, I can afford to take some of it back with some neoprene seat padding, as before. But first I tried a pair of Moto Skivvies (review) – padded undershorts made for motos not cycling. I’ve known the name for years but the 300L has pushed me over the edge and into their shopping cart.

Riding the lowered bike

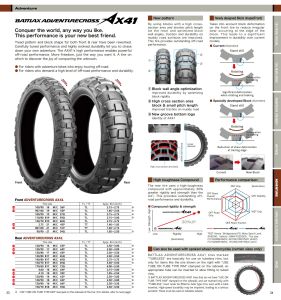

By the time I’d jacked up the rear preload a bit and had a 130/80 17 Mitas E07 fitted, the bike didn’t feel a whole lot lower. Measured, it’s now 33.5″/851mm with the forks raised up in the clamps all the way, so almost exactly the 1.75″ claimed. For the next 4000km over a month, the bike rode the same on the dirt; maybe a bit better all round with a fatter Mitas all round (now properly sealed for TL by the mechanic).

Getting on and off still wasn’t a whole lot easier. I use the footrest where possible, but having the tail pack on the side would ease a leg swing. Thing is, a tailpack is so darned easy; on/off in 4-5 seconds with a pair of Rok Straps. No other actions required and no side-panel scuffing.

The suspension still works great, just like it always did. I think the taller tyre may have touched the mudguard on one or two bottoming outs. I have to take a little more care when stopping and putting the stand down, but all in all, an easy, inexpensive and recommended mod if your stock L is giving you nosebleeds.