Tubeless Conversion Index Page

Updated 2025

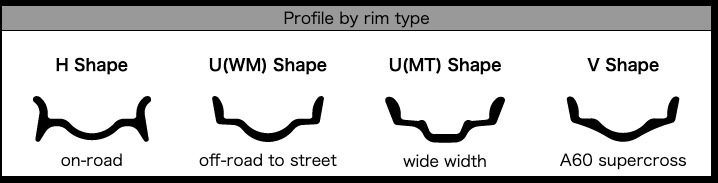

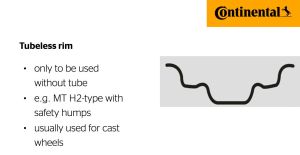

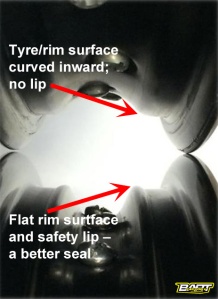

Tubeless rims are usually cast wheels with a lip or ridge (left) to help locate and seal the tyre bead securely on the rim. This lip is also considered a safety feature which stops any tyre coming off the rim should the tyre deflate on the move. In my experience, it works. You will feel the softened tubeless tyre long before it comes off the rim and can keep riding slowly without it coming off. These ridges have been a feature on the rear wheel only of some tubed motorcycles since the 1980s.

The ‘MT’ or ‘2H’ (‘H2’) rim code

Spoked rims with the safety lip suited to TL tyres are often stamped ‘MT’ on the rim, as opposed to ‘WM‘ or nothing, but usually only by Asian rim brands like Excel Takasago, but not SM Pro. As said, even bikes running inner tubes may use an MT-type lipped rim (which questions the claim that ‘you can’t put a tube in a tubeless rim’). European brands may use ‘2H’ (‘2 hump’) to mean the same thing, as with the Motad wheel below right who now own the Akront brand.

But as AD comments, his 2005 KTM’s German Behr rim (no longer made) was stamped MT but has no lips, so … [not] all MT-code wheels have the safety lip. What’s more, other rim brands like Twenty (below left) may have the lips but don’t use any discernible code on the rim. The only way to know for sure is to verify the profile of the rim.

This lip also makes removing and mounting the tyre difficult by the roadside if you need to repair an inner tube. It varies from bike to bike and tyre to tyre, but with tubeless you only need to remove a tyre to replace it when it is worn out (or destroyed), not to fix endless punctures. And unlike punctures, fitting a new tyre is usually done at a time of your choosing and in a tyre shop which has the know-how and tools, including a powerful compressor and lube to force the new tyre over the lips and into the rim’s groove with a nice ‘pop’. See this.

For years and years bikes running tubes also have this safety lip, but never on 21-inch wheels. Old Yamaha XTs like the one above had it on the rear wheel. Out of interest, this disproves another tubeless urban myth: you can only stick a tube in a TL rim to ‘get you home’ because it will eventually rub on the lip and explode with terrible consequences.

Well, clearly not on a stock tubed ’86 Tenere with a lipped DID rim (above). I know because I remember putting that bike on a crate with the rear tyre removed, sticking it in gear and ‘hand-lathing’ off that safety lip with a chisel so that I’d not get stuck in the desert trying to break the bead to fix a flat. And as importantly, remounting it with – back then – just a bicycle pump. All this faffing is why we like tubeless!

But to convert spoked tube rims to tubeless, these lips are an important safety attribute. My 2008 Tenere (above) had them on the back wheel. The front rim was normal which is a risk when converting to tubeless. But can it be any worse than a tubed tyre puncturing? Tubed tyres deflate faster and therefore more dangerously than tubeless tyres, so even without the safety lips or humps on the front, with tubeless you’re already ahead. But, as I found, with no lips you may get slow leakage along the seal. These days I would not convert any spoked wheel which did not have these lips (usually OEM 21s), even if it gets expensive.

Pictured left: the top ‘WM’ rim has no sealing lip; the lower ‘MT’ rim does. Note also the angle of the tyre bead–rim interface; the lower rim with the lip is flat which helps make a better seal and keep the tyre bead in place. The upper lipless rim slopes into the well making it easy to mount by hand, but it won’t hold or seal a tubeless tyre half as well. My 2008 Tenere front-wheel sealing problems were because the rear wheel was like the lower rim – good for tubeless. The 21-inch front was like the upper rim; less good seal.

21-inch spoke rims with safety lips

I spent weeks online tracking down a 21-inch alloy rim with the safety lip suited to converting to tubeless. They used to be rare, but not anymore it seems, as OEM spoked tubeless wheels become a ‘thing’ on adventure bikes.

Taiwan-based Giant (or GLM) is the biggest bicycle and motorcycle rim manufacturer in the world. They make such a rim in ‘big bike’ 2.15 width with 36 holes (bigger BMWs have 40; lighter trials bikes have 32). In the UK Central Wheel Components sell them for £111 (2.15kg) + 24 quid to anodise. It may be branded SM Pro (see bottom of the page). Rally Raid use this rim on their own wheelsets with BARTubeless conversions for Africa Twins (left) at a staggering £1500 a pair.

A quote to build that rim onto my Himalayan hub and seal it with BARTubeless (done in Italy) came in at £420. A quote to do the same for my AT: new 2.15 GLM rim £135; S/S spoke set and wheel build £105; Airtight TL band £120; post £21 (£381). Some claim the GLM rim is a bit soft.

More research unearthed Japanese Excel Takasago TL rims in 21-inch, but only a 1.60 size (left; p/n ICK408, and below) which is OK for dirt bikes but not adv twins. Talon in the UK import them at £165; I bought a pair in Italy for a lot less and have kept one for a rainy day. This rim has an unusually deep well which should make for easy tyre mounting, even after you’ve sealed it whichever way.

In 2018 there was talk of Excel making a wider 21 x 2.15 suited to bigger bikes and in 2019 it was produced, apparently. And in 2021 a mate bought a 2.15 x 21 SM PRO Platinum from Central Wheel for £135, as mentioned above. So these 21″ MT rims are out there now in black or gold.

Pingback: Tubeless Wheel Conversion for My Africa Twin - Points Unknown

FYI … the OEM Behr 21×2.15 rims on my 2005 KTM 640 have an MT code, but don’t have the safety lip, so it’s apparently more subtle than seeing an “MT” on the wheel code. This Avon document (https://www.avontyres.com/en-us/tyre-care/avon-tyres-moto-guide-2019-us-lr.PDF) provides a clue as to the difference between wheels with the WM code versus the MT code, but while it may be true that safety-lip wheels have the MT code, it doesn’t appear to be true that all MT-code wheels have the safety lip.

LikeLiked by 1 person

Hi I have done this conversion and running tubeless tyres on my 2009 ténéré for nearly two months now. But make me think again, is this safe?

LikeLike

Assuming you have done a good job, the worse that can happen is the tyres go down slowly and you don’t notice.

So fit a TPMS kit – 30 quid on ebay – and keep track.

LikeLike

Are there any 19″ rims suited for front wheel tubeless conversions?

LikeLike

Any spoked rim can be sealed assuming it’s in good shape (In true and rust free).

But the safety lip mentioned helps a lot – I am sure Excel etc do them – and of course the sealing needs to be done well or professionally.

LikeLike

hi chris, just done my 2106 AT 21 front, (no lip) did the rear 8k ago and it was a resounding success. Im just monitoring the pressure for a week to see what if any loss occurs. I have used the 3M tape diy method.

I think the other thing to consider on tubed rims is the serrated surface on the inner of the rim which can allow slow air leaks. I am about to experiment with sealing products in the tyre which should help with minor leaks. also it has been suggested to me that if the tyre is not tubeless ready there may be a more porous than a tubeless ready tyre??

LikeLike

Good to hear, Paul. How did you do the rear – 3M also? Did the I’m have have a lip. as some rears do? And did you do a dab of glue on each spoke end before taping over? Good point; I can see the serrated surface might limit a good seal and nothing to be lost adding Slime. I was told by a Michelin man that TL tyres have a non-porous coating, but also that there is no obligation for wire wheel rims for tubed tyres not to be porous. TPMS is the answer!

LikeLike

Yes Chris, used the M3 on the rear and it did have the lip.didnt put anything on the spoke ends. My view is that the pressure in the tyre is working in the favour of the seal, pressing the tape against the spoke ends. I have had three tyres on the rear ( Mitas E10) I think the critical area for air loss is the tyre bead against the rim because I have seen vetting results with the tyres for zero air loss to 2/3psi per day.

I have a product which I use in industrial/agricultural tyres, it’s a nine glue based inert carrier fluid with fibre & rubber particles that seals leaks by being driven into the hole by centrifugal force. It’s not glue based like other products.

LikeLiked by 1 person

Very interesting article Chris. My experience was limited to a 640A to which I had both the standard rims sealed. The rear worked fine, but the front often got sand in between the tyre/rim – followed by slow deflation. But worse than that, I have had instant flats where the seal failed completely! The problem was solved by using a tubeless-type tyre (eg TKC 80) as opposed to the offroad tyres (eg Mitas). Since the 640, I now limit rim sealing to the rear only – as dealing with front punctures is relatively easy; but the best advice is to watch carefully where you place that front wheel whilst offroad!

LikeLiked by 1 person

Thanks Jonathan. I think TL seal gets limited when pressures get very low. Don’t know how low you got.

21s have long been dodgy but I’ve just done 1000 miles on a Tublss and it’s holding up fine according to the TPMS. But because the tyres are knobbly (Mich Anakee Wild – like TKC) and it’s mostly rocky mtn tracks, and occasional slimy clay and mud, I can afford to leave them at road pressures.

In a few days I’ll be in the desert sands, but even then I won’t go much below 18 (1.2) all round.

I am trying to track down the safety lipped 21-er Giant rim. Still needs sealing, though.

LikeLike