Tubeless index page

Serow index page

The answer was one of these. I should have bought one years ago.

With the rear wheel off to check over and fit new bearings, I removed the Serow’s tubeless Pirelli MT43 trials tyre to fit a right-angle valve so as to end airline forecourt faffing once and for all. The Serow’s rear wheel only is an early example of OEM spoke tubeless. It’s even stamped with ‘tubeless tire applicable’.

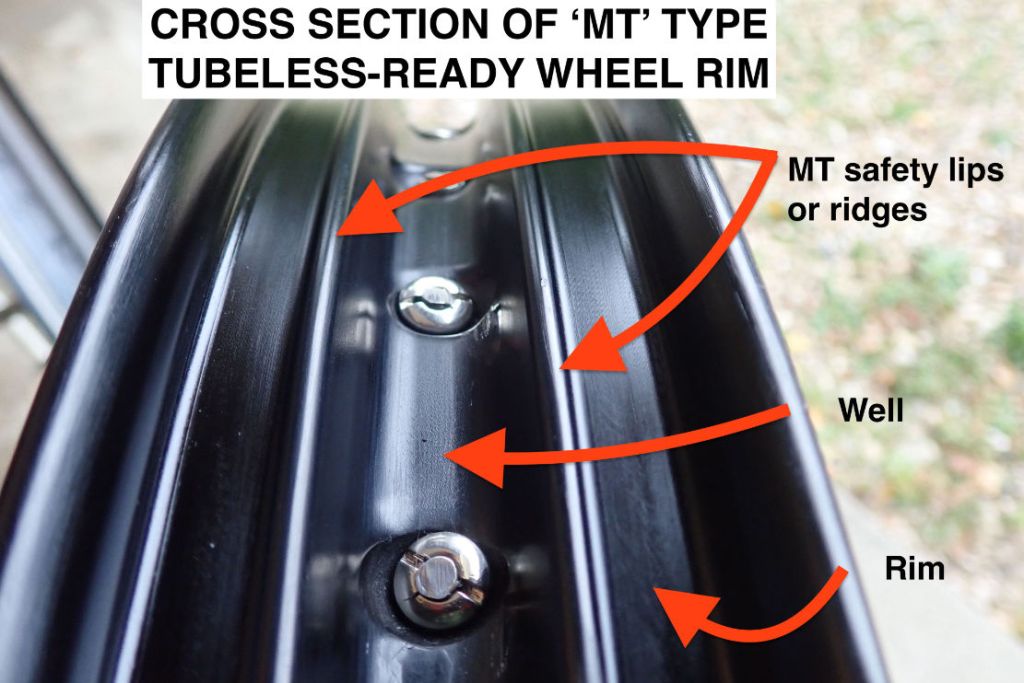

Levering the tyre back on, as I aired it up the tyre beads (edges) would not seal and mount onto the rim. With no inner tube to push it out, more pumped air was escaping than stayed in. It’s a common thing fitting tubeless, but with the valve core removed to maximise airflow, a bit of jiggling and pushing usually gets air going in faster than leaking out, pushing the beads against the rim’s MT lip. Once that happens, pressure quickly builds up, forcing the beads to ease over the lip and onto the rim with a ‘pop’. The job’s helped with a fast compressor like my 2.3 cfm Viair.

But not this time. Maybe it was something to do with the 4.00 18 Pirelli’s tall, thin sidewalls. Next, I tried the well known ratchet strap method, as I did on my XT660 years ago (below left). No luck. Rubbing my chin, I thought about the Icelandic method: injecting fuel through the valve hole, followed by a lit match. But that hadn’t worked on the XT either (below right). With the XT it had been just a matter of hours jiggling, pushing and pulling with the ratchet on, although having the brains to turn the car engine on gave the pump the extra poke it needed.

After doing a bit more of that on my Serow wheel without success, I tried jamming bits of plastic tubing into the unmounted gaps (left). They should slow the escaping air enough for pressure to build up inside for the beads to catch. Not this time (have I said that already?). All they did was push the bead further down into the well.

So I turned to the bicycle inner tube method which years ago worked on my Land Cruiser, fitting five tubeless tyres by hand in the back yard. Lay the wheel rim flat on a bench so the tyre is unsupported and the lower bead presses down onto the rim’s lower edge. When a moto wheel rests on its disc rotor or sprocket, this happens anyway. That should get the lower tyre bead to press or at least rest on the wheel rim, reducing air loss.

On the upper side, jam a soapy bicycle inner tube into that gap. I didn’t have an 18″ tube so I knotted a 29er, lubed it up, shoved it in and gave it some air. I tried for ages but this didn’t work either. I tried another compressor – same. It was the end of a hot day; perhaps the low air density was having an impact? I whacked in some CO2 cartridges I’ve had lying around for years. No change.

I emailed a pal who’s Mrs also runs a 250 Serow. He confirmed that for some reason, it’s near impossible with this rim/tyre combo, even with something called a beader mousse. Take it to a bike shop, he said.

I’ve not heard of beaders. He linked to a Trials shop which sold them for 30 quid: basically an 18-inch neoprene ring, like a solid pushbike inner tube mousse and a bit like the pushbike inner tube trick. Maybe it’s needed with modern trials bikes which these days run 18-inch rear tubeless and like me, have mounting issues. Note in the video below how the well-lubed ring handily squeezes itself out as the tyre pressure builds up, even with a handpump. Iirc, with inner tubes you have to pull them out before they get jammed.

It cannot be that hard so next day I gave it another go, hoping some knack might have manifested overnight, as often happens. I tried rings on both sides with whatever I had lying around. No good. But this is what worked.

With the wheel flat on a bench and the tyre pressing down on the lower rim, as described above, where the upper tyre’s well-lubed bead was clearly off the rim, I lifted it out with a tyre lever then slowly levered it back down onto the rim. This either put it closer to the rim or right on it. No inner tubes, ratchets or mousse rings. With the tyre well lubed this simple move did the trick. Turning the pump on, in seconds the motor’s drone strained reassuringly as bead caught, and a few seconds later both beads popped in place. Now we know.

Blocky trials tyres are actually pretty effective for technical UK trail riding, as opposed to the more obvious knobblies, though neither are great for setting IOM record laps and wear fast.

Like a 4×4 sand tyre, at very low pressures the thin sidewalls flex out to e l o n g a t e the tyre’s footprint, giving tank-track like traction. In the late 70s I remember doing a little enduro at Badgers Mount in Kent on my TS185 (above left and below). Against PEs, Bultacos and the like, I wasn’t a contender of course, but in the muddy woods at jogging speeds my trials-tyre shod TS had grip like no other tyre I’ve ever tried.

Chris, The thing that works for me on tubeless tyres is doing a speeded-up ‘Riverdance’ on a Halfords twin-barrelled foot pump, plus lots of tyre soap. I did a comparison between this pump and a motorcycle electric pump and the foot pump, at maximum ‘dance’ speed, gave about twice the flow rate of the electric pump. Dave

LikeLiked by 1 person