Not being a UK model, it can be a bit of a lottery ordering parts for the Serow, but generally it seems any XT250 from the same years is near identical. They’re not UK models either, but there seems enough around online in the UK. Webike.jp is the best I’m told, and pretty fast. Procycle in the US was amazingly fast for some TW200 parts. Oregon to my door in 3 days with a free sonic boom!

The chain is only a skinny 428 (next size down from 520), but a heavy duty got fitted which looks nearly the same as a 520. There’s a lot of caked-in Salisbury Plain mud splattered all around the nooks and crannies and a bit of surface rust, but nothing drastic.

• XT250 air filter for a tenner off ebay. Never seen one that small.

• Rear wheel bearings. The bike was used for muddy UK trail rides and the bearings didn’t feel that smooth and solid. Again a lottery if not buying factory parts; I took a chance and these were the ones.

I did some front bearings once but not rear bearings – never knew there were three in there (two on the chain side; no cush drive, like the CRF).

I expected the usual gnashing of teeth, but it was dead easy after a quick YouTube and and no special tools required. I peeled out the rubber seals with a tyre lever, heated the area over a camp stove, then used a thin, long, round rod with a freshly-sawn sharp end to tap one out, starting on the brake side (single bearing). There is a spacer tube between the bearings along which the axle normally slides, but the bearing’s inner diameter is 1mm or less smaller, which provides a smidge of a lip for the rod’s edge to work on. Once the spacer drops out, the chain side bearings are easier to tap out.

Once greased up, the new ones gently tapped in easily (no need for freezing to shrink them), using a large socket on the bearing to spread the load evenly, and the bikes axle to help line up the last bearing and spacer tube. So satisfying when it all goes to plan.

• Trail Tech engine temperature read-out. There are Chinese cheapies on ebay for 20 quid but for 3 times the price, I know well that a T’Tech will last (left: WR250R). Clamp the wire anywhere very hot then learn a median reading so you know what’s excessive. Air-cooled run hotter so it’s good to keep an eye on things and slow down if needed. My Him 411 got up to 270°C on the motorway. The battery powered read out is handy to read ambient morning temps too (left), before starting the engine.

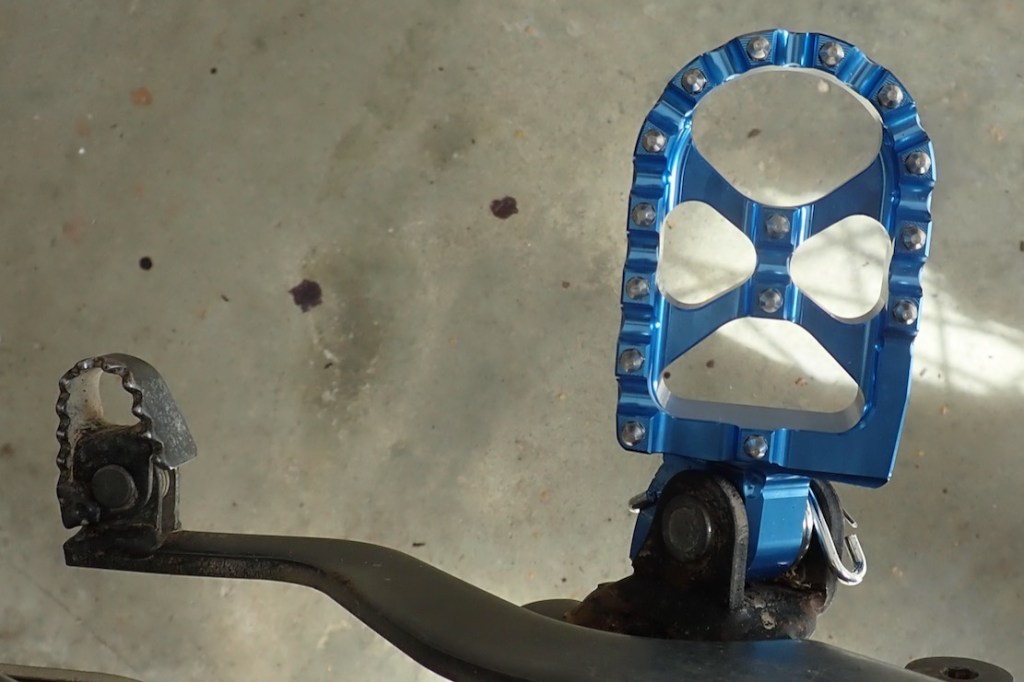

• Replaced the stock cheesecutter pegs with some full-fat WR footrests I had left over. They only came in blue – or black costs loads more.

• As usual I wonder about upgrading the shock; an easy way to improve the off road ride. But I forget that stock Yam 250 suspension is not necessarily the soggy mush off a CRF. The TTR had great suspension, and it seems Serow (especially the previous 225) is closer to TTR than the 250 Serow which has no damping adjustment. In the RM vid below, matey is swapping out a stock 6.7 kilo spring from a US-model XT250 for a Racetech 9.8. It seems a pretty easy job with no deadly compression required. I don’t know what my spring rate is and whatever damping I have left comes free.

The YSS shock is the cheapest at £330 with compression damping and a juicy red spring which must be worth 50 quid alone. A YSS was OK on my Himalayan 411. Internally I’m told they’re crude, but YGWYP4.

I thought about it, then held off and instead chipped away at the preload rings with a hammer and old screwdriver, assuming I need more than the orevious owner who was probably half my weight. The rings were now ⅔s down the threads but adfter a ride along a bumpy lane it was way too much. Back home more chipping to back off a bit. The unadjustable front fork also seems usefully firm.

So maybe the suspension is not so bad after all, and now knowing the shock can be easily removed and taken apart and the spring is firm, it would be great to fit a hydraulic preload adjuster (HPA; above left). I’ve had them on previous bikes: just turn a knob to vary the spring preload depending on loads or terrain. You can almost do it while you ride. Who needs ESA? The problem is finding one that will fit what is probably a KYB shock. There is space enough around the shock for the hose and mechanism, but along with the exact diameter, I’m told there is no commonality with shock body threading like there is with other screwed fittings.

If I don’t manage to find an HPA, I’m eyeing up a Hagon shock with combined damping/compression adjustment and an optional HPA (left), all made to measure in merry old England for 600 quid with a plain black spring.

Back in the 1980s I used to get the fragile stock wheels respoked at Hagons when they were in Leytonstone, in the day when I rode full-sized XTs.