The other evening I had a great idea while riding my MTB along a Purbeck ridge. My Merida hardtail bike (left) has a dropper seatpost: thumb a lever and the saddle drops 6 inches under your weight; press again with your weight off and the post springs back up to full height for efficient pedalling effort. Far from another MTB gimmick, I use it all the time when approaching a gate, on steep downhills or even just getting on/off or stopping to look at the map. I think motos could use a similar feature when off road: there are times you want it high and times you want it low, with no faffing in between.

Automatic ride height adjustment as found on some H-Ds and BMW 13GSs is not the same thing. Nor is static saddle height adjustment by repositioning the seat base on its mounts; the sort of thing you usually do once. The main reason I never got the otherwise great XT700 back in 2019, was the seat was too high for what I like to do.

Do all-terrain motos really need dynamic seat height adjustment? Well, until MTB droppers came on the scene, I’d have said ‘no’ and managed by manually dropping saddle for rough descents. On a moto, a high saddle – or more precisely a long peg-to-saddle distance – reduces the effort of standing up and is why competition bikes have yard-high saddles: dirt racers are on the pegs most of the time.

Those bikes are of course feather light and easy to manage in the rough. Bring a similar saddle height to a 230-kilo loaded travel bike, like the Desert X Rally I rode with (below), and tackling rough stages requires skill and commitment, assisted by plush suspension and good armour. I can tock off all four, but I do find some low saddles (above: Him 450) a bit hard on the knees, even if I can reassuringly get my feet down.

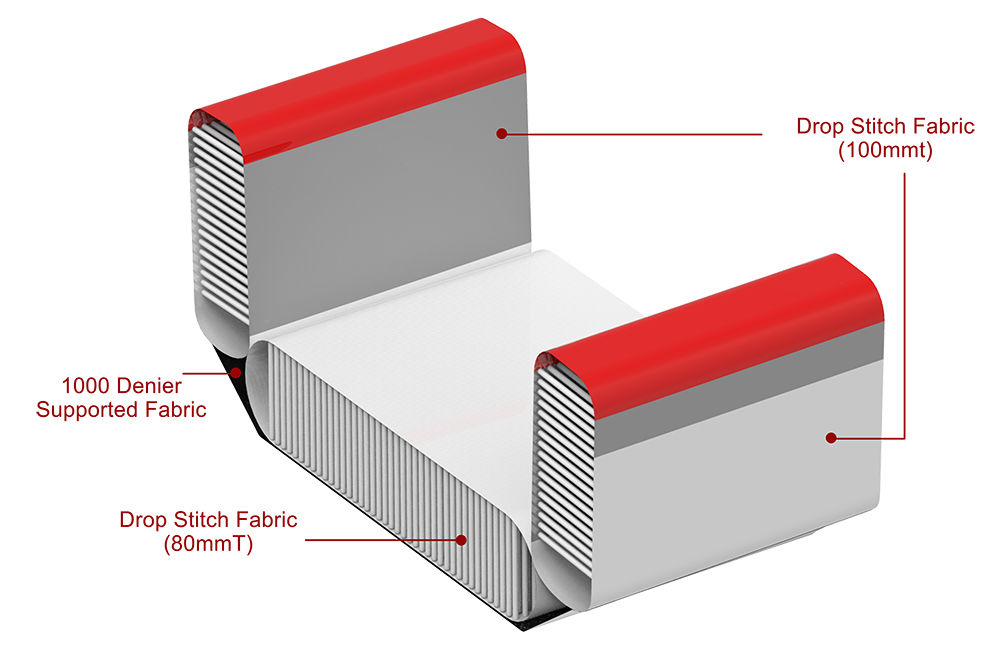

My brilliant idea uses an inflatable chamber integrated in the bike’s seat foam, tech I know from inflatable kayaks. IKs attempt to mimic the hydrodynamic form of a hardshell kayak and a few years ago drop stitch panels from paddle boards were adapted to make boxy, ‘3-plank’ IKs (below right).

Drop stitch (DS) panels hold much higher pressures than tubes (15psi+ vs 3psi on I-beams) while retaining the flat panel shape. The result is hardshell-like rigidity with the transport and storage convenience of a roll-up kayak. Decades ago, Goodyear even developed a drop stitch airplane for the US military.

For this moto seat application, it’s not about rock-hard rigidity, but being able to increase saddle height by 2-3 inches while retaining a normal looking moto seat. The bladder could be integrated in the seat vinyl which would need stretchy sides or some other idea so as not to look crumpled when set low and not to wobble about like some non DS air seat pads.

Sadly, my pitch stumbles when it comes to inflating and deflating this chamber at the flick of a switch. Exhaust gas being too hot, some sort of separate on-board compressor would be needed which adds weight, cost and complication. And you’d want a fast purge valve because when you want less height, you probably want it fast.

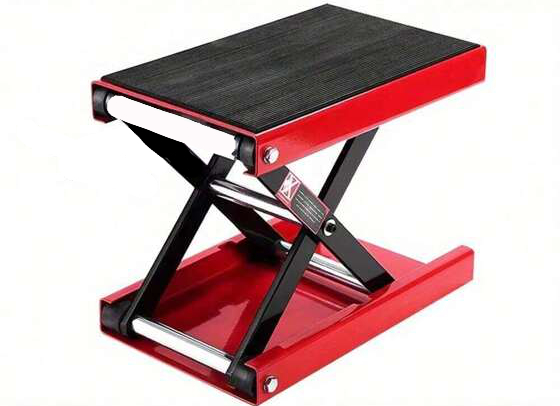

PS: I have to admit Dave K’s comment suggesting a scissored lever with similar click/release mechanisms to a pushbike dropper is much better. On the jack pictured below, the base is the bike’s subframe rails and the top is the seat base. The seat is raised by spring/s under compression to engage a lock-out to stay up. A thumb lever cable (a bit like the old compression release lever on an XT500) disengages the upper lock and, aided by body weight, the seat drops to lock in the lower position. Thumb the lever again and it springs up, but ideally with a bit less force than 007’s DB5 (right).

Issues I foresee include retaining a secure seat when raised. You don’t want it wobbling about laterally when bashing about off road which may mean hefty beams. Alongside that, the inelegant gap in the raised position could be designed around.