When I think back to my early travels, the idea of doing anything more than just jacking up the shock to carry the load never occurred to me. With suspension, it has to be pretty terrible for you to notice, and for that to happen – or for good suspension to show it’s worth – you need to be either riding pretty fast, or hammering over rough terrain. If you don’t do much of either or don’t have up to a grand to spare (or have good, fully adjustable forks) it’s not worth it. But for under £100 it is possible to improve a non-adjustable fork’s damping action. And my Serow could do with some of that.

Can’t be bothered to read another word, but still curious? Watch the 12-min vid at the bottom

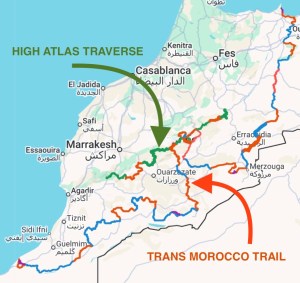

On our H.A.T recce in Morocco last November (left), right off the bat the Serow’s front end was all over the place on stony climbs. Notably worse than other bikes I’d ridden lately. It never bottomed out and the back end wasn’t sagging, so I presumed it was a combination of too stiff front tyre and negligible damping, that inscrutable function which controls spring rebound.

‘Spend a grand plus taxes on a full, US-imported Cogent front and rear Serow set up‘ they said. ‘Night and day or your money back!’ Cogent also do a fork kit with drop in emulator valves, replacement springs plus oil for around $400. I didn’t need a new spring or oil, only valves, just to end up with better, but still unadjustable forks. Next stop were Race Tech Gold Valves for $230 (FEGV 3311). Still quite a lot with import tax and all, and unlike Cogent, you need to drill extra holes in your damper rods (a lot of added work). You’ll find much online chat about the pros and cons of Cogent vs Race Tech emulators. Like here.

Long story short, widely sold in the UK YSS also do a range of emulator valves for just 90 quid (below). They’re not gold, and I’d need to drill the rods but as I needed a new fork seal anyway, it seemed worth a shot to DIY, even though I’d never taken forks apart before.

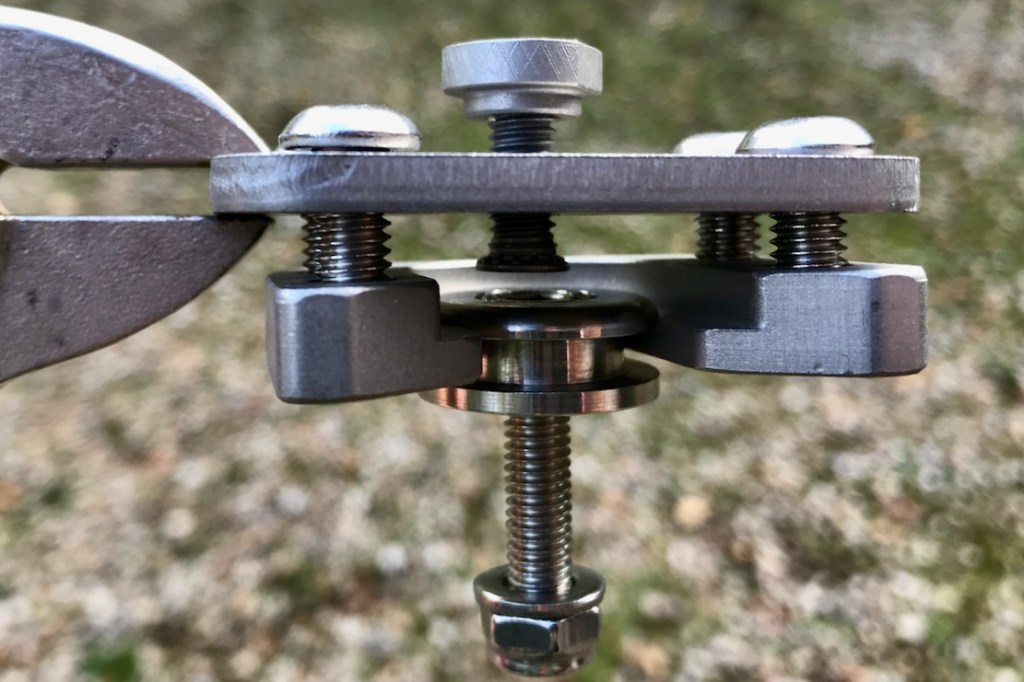

I’d heard of emulators but wasn’t really sure what they were. Turns out they’re easily fitted valves which enable conventional, archaic damper rod forks to ’emulate’ supposedly superior cartridge forks (Cart-what? For another time).

The valve (above left) is a preload adjustable spring loaded plunger which sits between the fork’s fixed damper rod and the spring (right). As forks compress, oil is pushed through the valve, opening the sprung valve which is otherwise closed. Oil flows through progressively relative to force, compared to static conventional damping rods with just a couple of drilled holes. The vid below made similar Race Tech installation on an XT500 look relatively easy. If only.

You need a set matching the internal diameter of your fork tube. For a Serow it wasn’t possible to find that info online, and guessing from the fork tube outer ø is sketchy (I now know…). The best way to verify your fork tube’s internal ø is to undo a fork cap, lift out the spacer/spring, and measure ID with some verniers. On the Serow fork ID was ~30mm – not my 31mm estimate. The 31s got sent back for exchange but never made it. But by chance I found some next-size-down YSS 29s used on ebay for half price. Weeks passed by for all these fascinating events to work themselves out.

If it was only as easy as the slick vid below with a well lit and superbly equipped workshop and dinky music tinkling in the background. Whip out the springs, tip out the effortlessly unscrewed rod, pop in the new valves and reverse the rest before damping progressively into the sunset. My damper rods didn’t slip out nicely (and wouldn’t have easily dropped back in, either) so the entire fork leg needed to be disassembled.

Unless using drop-in Cogent valves, you need to get your hands on the damper rod because additional holes must be drilled for oil to pass unfettered up to the new emulator valve. A hex bolt at the base of the fork secures the damper rod inside the lower fork. They’re notoriously tricky to remove because it’s like trying to undo a bolt from an unseen uncaptive nut without any means of restraining the nut.

‘Get a rattle gun’ I was advised (left; pneumatic impact driver), to ‘shock’ the allen bolt from the damper rod to which it’s been seized for the last 15 years.

I have an 80-bar compressor tank and found a 25 quid rattler on ebay – ker-ching. But air gun shock therapy wasn’t working. The rod was spinning inside – as you’d expect. A ha, I thought, I will ram a whittled stick in the other end to stop the rod spinning, lock it off with some Moles (below left), then apply rattle. That worked – eventually, but on reassembly it didn’t, so I deployed the ‘broom trick’ I’d seen mentioned online. Same idea: slide it down the fork tube to press against the damper rod top, then pull the trigger. Long arms or step ladder needed. All this seemed a bit less faff than entirely reassembling the fork (as suggested in the vid) to add tension to the rod for removal/refitting.

Much faffing later (have I mentioned faffing yet?) I had the forks in bits by which time I realised I could have fitted the new fork seal myself, not at the LBS.

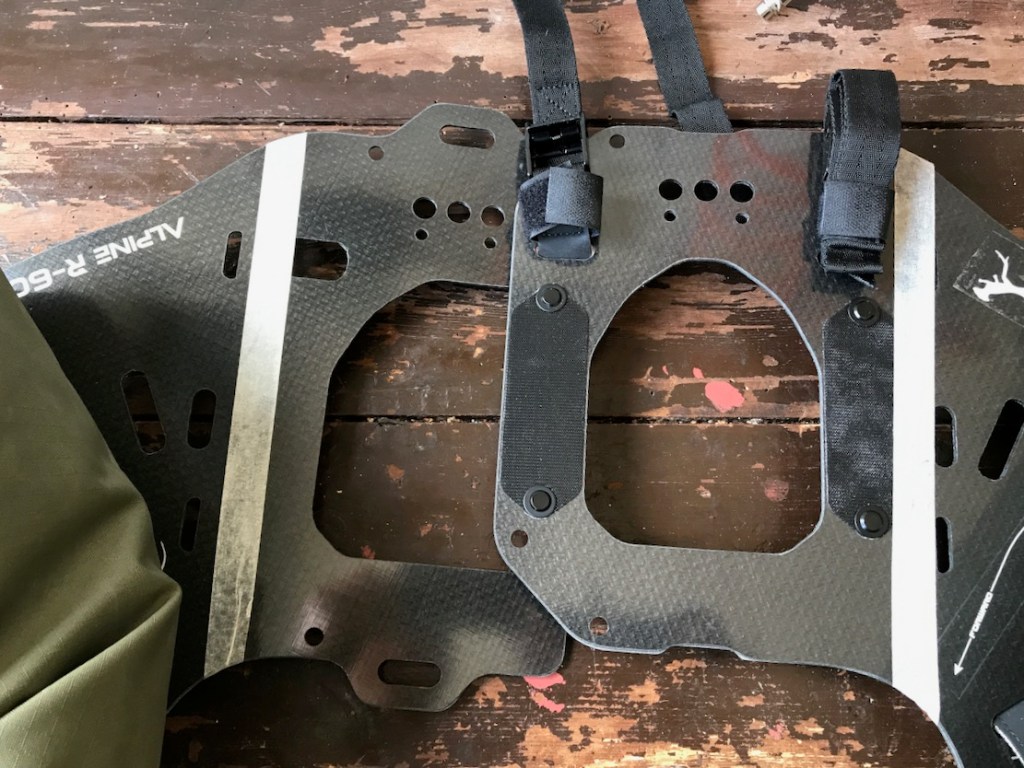

To maintain your fork spring effective length & vpreload (FSEL&P) and not void your insurance, you need to saw off the effective height of the valve’s body – about an inch – from the spacer tubes so it all fits back together again (below). A fairly easy job even I’d find hard to mess up.

Next job was drilling several extra flow holes in the damper rods which normally have just a couple near the bottom. Like much of the Serow, this is 1970s technology, maybe older, but I suppose it worked well enough. Additional holes allow the oil to move up to the sprung emulator valve which controls the variable flow. Another thing I learned: on Serow forks the drilled rods pass through a close-fitting nylon collar at some stage of reassembly, so any protruding burrs left over from the drilling will lock the fork action. Grind the rods smooth to slide through the collar smoothly, then clean off any remaining swarf with solvent.

By now Christmas had come and gone, so had New Year and there were already chocolate eggs in the shops and daffs blooming. But I was getting close and the forks now slid smoothy in and out, like they should. I did the ‘broom trick’ as mentioned above to tighten the rods back onto the fork leg with the air gun, and was so amazed it worked first time, I stopped right there and took the rest of the day off before another cock up kicked me in the nuts.

“Refitting is the reverse sequence to removal.” to quote M Haynes, and amazingly, only one bolt had escaped in the weeks it took to complete a one-day task. But let’s snatch a positive from this elongated fiasco (above ;-): I’d leaned all about damper rod fork internals. Having avoided fork disassembly all these decades, I can now see they’re not so complicated, at least old-style RWU forks. USDs, who knows, but it’s said that, apart from fork seal weepage, they’re more complicated inside but are often higher spec and have adjustment, so emulation maybe not needed.

Amazingly, a simple circlip appears to hold the two parts of a leg together. Undo that and whack the two sections apart like a Christmas cracker to get to the seal or damper rod. Along with rod loosening, refitting a seal without damage and without the correct slide tool is probably the hardest job.

Deciding on fork oil weight and volume/height is another opportunity to tie yourself in knots of self doubt. I found several values online for the ‘XT250’ until I realised just measure the volume of watery, brown swill which poured out of the non-leaky leg – 350cc. On reassembly I poured in just 300cc of fresh 10W, thinking it’d be easier to add more if something felt very off, rather than try and suck some out. The damper and emulator valve is surely be submerged in the oil full time. I think oil volume is more to do with how much air remains in the forks and it’s effect on compression. Less air = more compression.

By the time I reached this climactic peak of enlightenment, the Serow’s previous owner got in touch, enquiring whether I knew anyone with a Serow Touring for sale. Someone must have told her I was a serial bike quickshifter! With Morocco snowed out and me elsewhere this winter, a deal was made and a date was set. I topped up the leaky rear tubeless tyre and took the Serow out for one last ride along Purbeck’s flooded lanes.

The forks felt the same – fine on normal roads, as before. No great surprise. I’d need to find a rocky climb to see if the front responded any better, but right now what few local lanes I knew around here where probably knee-deep in mud or carpets of rotting leaf sludge. On these tyres? I don’t think so.

So I puttered merrily around the Purbeck Hills I usually cycle in the summer and tried to think what could replace the agreeable Serow. As I did so, the sweet aroma of mud thrown up onto the hot pipe took me right back to my earliest days dicking about on Surrey wastelands with ratty trail bikes (left).

What trail bike was as light, low saddled, semi-tubeless, economical, started on the button and came with racks and a screen? Probably my CRF300L a couple of bikes back, but look at the huge amount of spending and work it required to reach that stage. I guess that’s why these old Serows hold their value.